new and used avionics

Sell Your Avionics Here

Sell Your Avionics Here

|

Avionics List

new and used avionics |

Sell Your Avionics Here

Sell Your Avionics Here

|

Buying Safety Tips |

Avionics Articles and Reviews

|

Let's take a good look at the purpose of the transponder, and get an idea how it operates. As you are probably aware, it's getting to be almost impossible to go anywhere without the transponder, and in a lot of cases the mode"C" function is a requirement also. Flying around in Southern California without mode "C" is hard to do anymore. I remember years back when an encoder was a luxury but today it's a requirement.

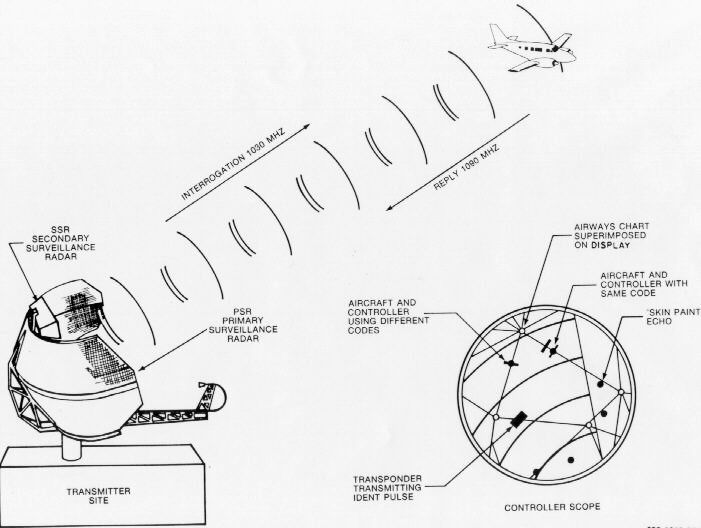

The purpose of the transponder

is for the ATC controller to locate and identify transponder equipped aircraft. .

Most ground stations have the capability to track both primary and secondary targets. The

primary and secondary radar systems are synchronized together. The primary

targets are aircraft (or flying saucers) that are not equipped with

transponders. What we

are referring to here is the reflection off the aircraft skin. Secondary targets are

aircraft with working transponders. When the controller sees the Secondary target, they

see the code selected in the transponder window along with Mode "C" altitude if

present. Composite aircraft may not reflect the radar back so without a transponder system

ATC may not see them at all. The controller also has the option to select only certain

codes or aircraft with mode C only. Often in busy areas, the 1200 VFR code is blocked off

the screen, so to get a clearer picture of the aircraft showing the codes the controller

wants to see. This is why it's important to always have your eyes outside in VFR

conditions.

Secondary targets are

aircraft with working transponders. When the controller sees the Secondary target, they

see the code selected in the transponder window along with Mode "C" altitude if

present. Composite aircraft may not reflect the radar back so without a transponder system

ATC may not see them at all. The controller also has the option to select only certain

codes or aircraft with mode C only. Often in busy areas, the 1200 VFR code is blocked off

the screen, so to get a clearer picture of the aircraft showing the codes the controller

wants to see. This is why it's important to always have your eyes outside in VFR

conditions.

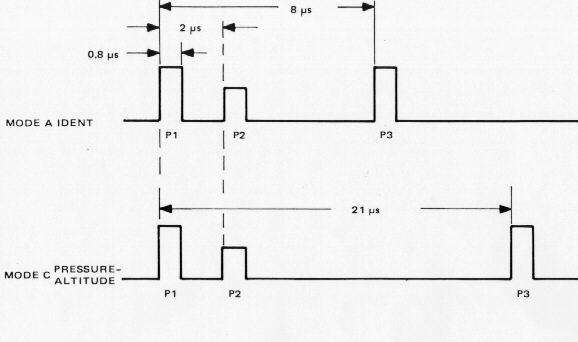

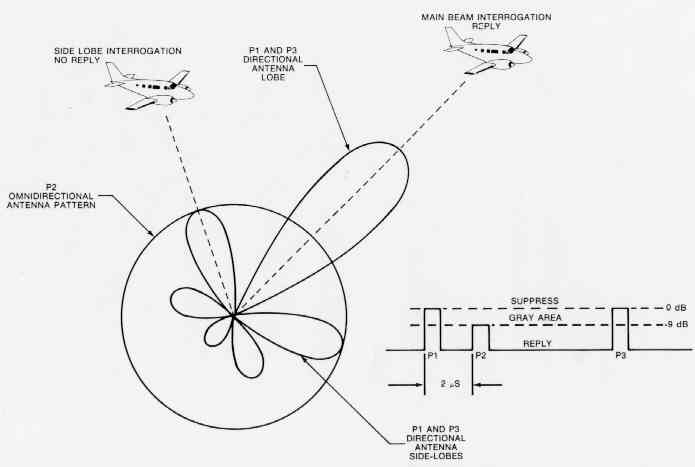

The ground station usually consists of three transmitting antennas, the Primary target antenna, the Directional antenna and the omnidirectional antenna. The primary target antenna only shows aircraft without transponders if they have a reflection. The purpose of the Directional antenna is to interrogate the aircraft so it will send a reply back down to the ground station. This antenna sweeps around and the controller usually gets a 360 degree view. The directional antenna also tells the transponder to reply to Mode A and/or Mode C. Mode A is the code that you have selected on the front panel of the transponder. Mode C is the altitude-reporting portion (if equipped). Usually the ground station can transmit up to 110 miles and transmits on a frequency of 1030 megahertz. The information transmitted back down from the transponder is then massaged and shown on the controller's screen. By now you are probably wondering about that Omni-directional antenna. That's the most important one of all. The omni-directional signal is very weak compared to the directional antenna. This antenna puts out a signal called P2. The directional antenna puts out P1 and P3. If P2 becomes anywhere near as strong as P1 or P3 then the transponder will not reply. The reason for this is, if you happened to be in what we call a sidelobe of the directional beam the ground station would see you somewhere where you were not. As you can imagine, this could be dangerous. One of the many reasons you have a bi-annual test of your transponder and encoder is to make sure these critical areas in the transponder are working as they should. If you like Take A Look at a drawing that may help you understand this a little better.

Now, about the transponders: Hopefully most of you have transponders with mode C capability. Actually some transponders have modes A, B, C and D. The only difference is the pulse spacing between P1 and P3. Usually mode B and D are used in other countries. I've heard that in some foreign countries where the aircraft only flies in that country, the aircraft is assigned a permanent code. To start, have you ever wondered how many codes are available to us? I guess on a cross-country trip, you could add them up, or ask the controller, but believe me, there are 4096 possible codes.

All aircraft transponders now must comply with TSO C74b or C74c. If yours doesn't comply with this TSO, then legally you can't even turn it on VFR, much less IFR. Almost all transponders do comply with this, but watch out for old Narco AT-50 and King KT-75 units. They might be illegal if not properly modified. The faceplates on most of our transponders are labeled as follows: Off, Stby, On, and Alt. Regardless of whether you have mode "C" Altitude reporting or not, you should be in the "ALT" position unless the controller says different. The ground station is looking for mode "C" framing pulses even if the altitude data is present. I guess "standby" is OK on the ground, but I usually forget to turn it on until the controller says, "recycle transponder". He knows that I've forgotten to turn it on, and it's his polite way of saying, "wake up, dipstick!" If your encoder for mode C takes a dive and starts putting out wrong information the ATC controller will have to "stop squawking altitude". At that point turn the selector knob to the "ON" position. Be prepared to get a nasty letter from your local feds if you encoder is off by more than 300Ft. Another thing to remember is if you left the switch in the "off" position and take off in IFR conditions, then ATC yells that they can't see you, I've got bad news. Some transponders take up to three minutes to warm up. Believe me that can be the longest three minutes of your life. At times the controller will have you to "ident". Notice that the reply lamp will stay full bright for about twenty five seconds. This is Normal. When you push the "ident" button this causes a mark on the controllers screen, making it easier to find you. This is basically just another pulse added to your already present code. Most transponders have the capacity to have a remote ident button elsewhere in the aircraft. If your transponder is hard to reach, maybe you should have your shop see if putting a remote Ident switch in is possible. The transponders output power is usually around 200 watts at the antenna. Some of the airline transponders run over 900 Watts! In my humble opinion, anything over 100 watts is a waste because it's all line-of-site BUT if the manufacturer says it must put out 250 Watts then that's where we set the power level. If you like, take A Look at Another Drawing to help explain this article.

You may ask, "how about the altitude reporting part?" Well, the first thing to remember is the Mode C is always referenced to pressure altitude which is 29.92" barometric pressure. The important thing to remember is that you should have your altimeter baro-scale set at the pressure the controller has given you. Now you say, "if my altimeter is set at let's say 30.23" and Mode C is putting out at 29.92 there will be an error on the controllers screen! The controller's computer will take the Mod "C" output based on 29.92" and convert it to barometric pressure at your present position. Now the controller sees you at the altitude showing on your altimeter, we hope... You just learned something, huh? According to the FEDS, the encoder and altimeter must be within 125 feet of each other. If you get too much error (normally 300") ATC will have to stop squawking altitude. This is not a good thing. At that point you should visit your friendly avionics shop to get the altimeter and encoder married. I would explain how they are married, but marriage is not by expertise. The encoder is tied into the same static line as the altimeter, and is wired to the transponder. Some folks have an encoding altimeter, and these are great, but fairly expensive. The advantage is they take less space and are easier to install. It is basically altimeter and encoder in one case. One Last Drawing to Ponder Over.

Why the bi-annual test you may ask? After all the transponder "seems" to be working fine. You part 91 operators take your aircraft to an A&P every year for an inspection even though you "think" the aircraft if running fine. You probably know too well that problems do show up during an inspection. Let's discuss what's involved with the bi-annual test of your transponder, encoding system.

In a nutshell FAA Far 91.413 states the transponder and encoder will be tested. This FAR also calls out what perimeters the shop is to check. The manufacturers specifications often give us the limits of the transponder such as power out and receiver sensitivity. All the codes are checked, power out, frequency tolerance's sidelobe suppression, reply time and a host of other things tested on the transponder. All the encoder output bits are tested along with the accuracy of the encoder. All these test are very important. If you fly the aircraft even VFR this test must be accomplished every two years. Logbook stickers or entries must be made. Don't get caught flying without being FAR 91.413 current. Bad things can happen if the feds find out. One of our customers got a violation because his encoder was more than 21,000Ft off at times. ATC was having to divert airliners in the flight levels even though he was only at 8,500Ft. ATC wasn't talking to him so they didn't have a positive confirmation of his altitude even though he was "squawking" 1200. I can imagine those airline TCAS were going crazy, traffic 10 miles ahead at FL 230 doing 120Kts! The fed investigated the guy and found his 91.413 certs were out and had been out for more than six years. They fined him $1,500.00 and went after the A&P who had signed off the last annual inspection. Not a good day for this poor fellow but you can imagine the problems he caused with ATC in the Los Angeles area!

FAA FAR 91.411 states the static system and altimeter must be tested every two years. If you accept an IFR clearance your aircraft must be current with this FAR. The altimeter is tested for friction, scale error, leakage and many other tests. We must verify that the static system doesn't have any leaks. Some leakage is permitted but it's very small. Pressurized aircraft must be tested up to their maximum cabin differential pressure. This is a real pain in a large aircraft such as a King Air but that's the way the FAR is written. If your aircraft has an air-data computer, then it must be tested. The computer manufacturer calls out what test and tolerances are involved. We normally find air-data computers in aircraft such as Falcons that have Mach limits. This test is not required for VFR.

Transponders made today are cheaper and far more reliable. In 1976 a new ARC transponder cost $2,460.00 and it was marginal at best. Today a new King transponder sells for around $1,700.00 plus installation. Properly install a new transponder and you should get a decade or more service of excellent service out of it. Most of the newer transponders are micro-processor controlled, thus there's few adjustments inside. I couldn't tell you the last time I worked on a modern transponder but those old ARC's, well that's a different story. Encoders are pretty bullet proof now days. If you've got one of those old Narco AR-500's and having a problem just yank it out and install a new model. It will be trouble-free for years.

My goal wasn't to go into a lot of theory but just give you a basic idea on how the transponder works in our ATC system. Hopefully you now see how important it is to keep your transponder system working properly and certified. Below are some FAQ's. If you have any questions feel free to drop me an E-Mail.

FAQ's

Do I need to have FAR 91.413

Complied even though I don't go into Class B airspace?

Yes, if you fly the aircraft at all, it must be certified per

FAR 91.413 by an FAA Approved Repair Station.

My transponder is broken, I'm out

of bucks and can't get it fixed at this time.What are my options?

The best thing to do is borrow some money or whatever and get it fixed. If that

isn't an option, you can remove the transponder, update the weight and balance, make a

logbook entry and fly in airspace that doesn't require a transponder.

My transponder

"Reply" lamp is always on when the DME is turned on, what's up?

Easy, my dear Watson. The

transponder and DME are talking to each other. DME and transponder operating

frequencies are close to the same and cross-talk can happen. Most transponders have

a "suppression" line that is tied to the DME to cure this problem. Old

ARC, Narco and Collins transponders do not have suppression. This problem in long

term can damage the transponder.

At times my DME will blank out with

the transponder on. What causes this?

This problem is basically the same as above. DME

suppression must be connected to cure this problem. Sometimes greater separation

between the transponder and DME antennas may help but that can be costly.

What is the average cost for

FAR 91.413 (VFR) test?

It varies from one region to

another. In my area the test runs around $90.00. This test takes between 1-3

hours.

What is the average cost for both

FAR 91.413 and 91.411?

Non-pressurized aircraft run on the average $225.00 if no

problems are found. This test takes between 2-4 hours.

My Transponder seemed to work fine before the test, but the avionics shop found problems anyway. Is this normal? Yes, on older transponders such as the Narco AT-50's and ARC RT-359A types along with the older King transponders are getting to a headache to keep aligned. As you saw from the drawings, alignment is critical. We are dealing with Micro-Seconds, that's pretty fast! The goal is to make sure ATC is seeing ALL the correct bits, altitude and the transponder is within manufacturers limits. This often requires adjustments.

ATC Control Beacon Set-Up

Propagation of 3-Pulse Interrogation Signal

3-Pulse Interrogation